Processes

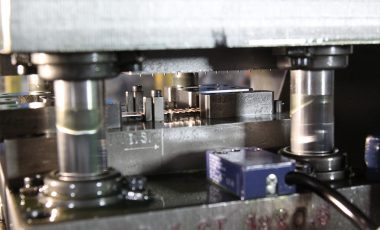

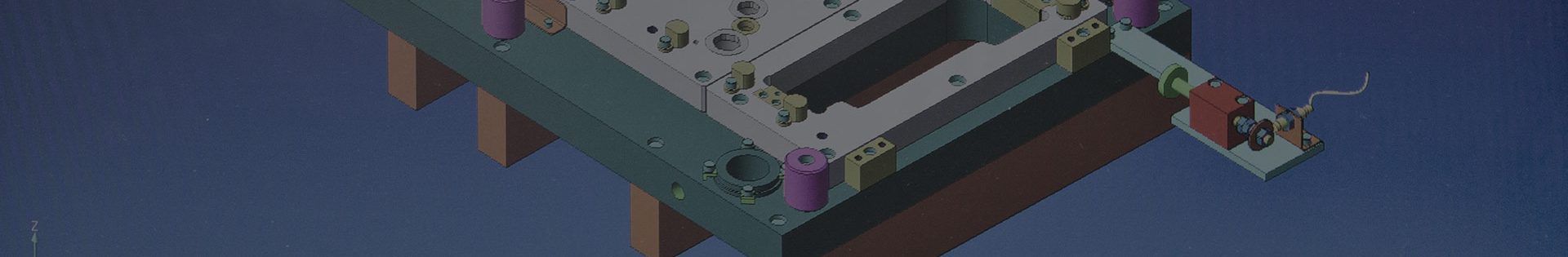

Die construction:

NUOVA SIMACH S.r.l.’s die construction department is equipped with avant-garde equipment including a CNC workstation, two EDM machines – one of which is state of the art – a sinker EDM machine and a small hole EDM machine.

The range of equipment also includes machine tools with visualisation systems, manual machines and work benches for assembling dies and complete tools.

All ordinary maintenance and emergency maintenance, as well as any modifications to dies requested by clients, are done on-site in the die construction department, thus guaranteeing expertise, precision and a quick turnaround.

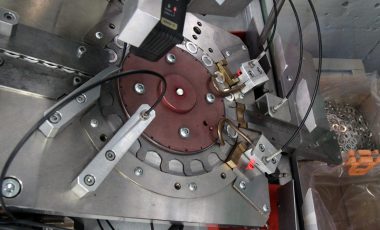

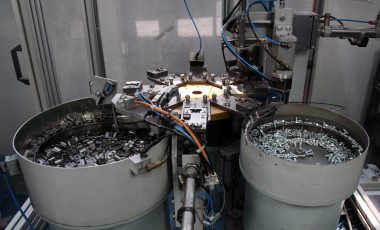

Stamping:

The stamping department is equipped with 35 mechanical presses ranging from 16-400 tonnes.

The production cycle is completed with the use of machines for shaving, washing and drying stamped parts as well.

The materials used to produce stamped parts include various kinds of sheet metal (steel, stainless steel, copper), alloys (bronze, brass, nickel silver) or special compounds (tri-metals), with thicknesses from 0.1-5 mm.

Products

Design