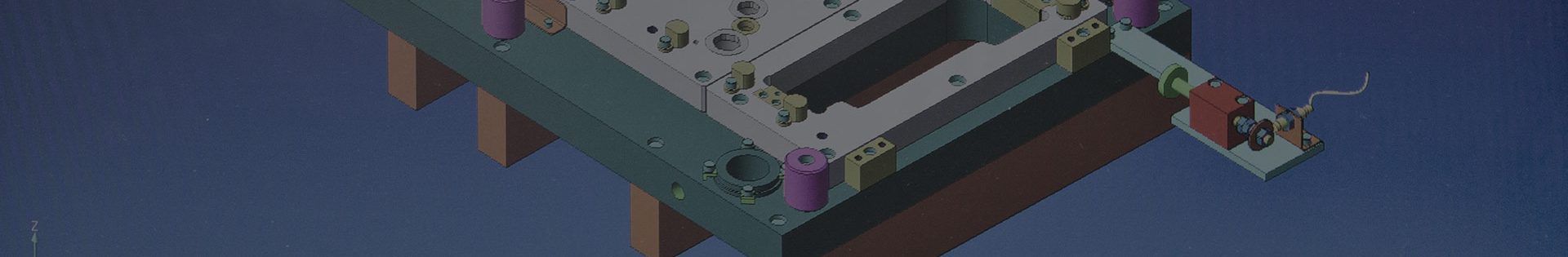

Design,

die construction and stamping.

NUOVA SIMACH S.r.l. is in Torre Canavese (Turin), Italy and covers an area of 11.000 square meters. Our Company was founded in 1977 and it is specialized in cold stamping of metal parts, from tool design and construction to mass production.

We are leaders in the production of contacts, fastons, also selectively treated, made from tape.

We produce busbars, brackets, supports, shields, covers, safety belts and, especially for vehicle electrification, we are specialized in copper, aluminum and steel stamping parts from 0.07mm to 6mm in thickness.

We support our customers from prototypes to mass production (co-design phase included). We carry out manual assemblies or arc welding with different technologies (MIG / TIG / Short Arc welding / projection welding for nuts. We can also provide customized packaging for different types of products.

We are supported by external suppliers for different special processing: total or selective treatments such as coating, insulation, galvanizing, tinning, nickel plating, silver and gold selective plating, gilding, varnishing, degreasing, burnishing etc..

We are direct supplier (TIER 1) of Volkswagen group (Lamborghini, Audi etc) and Ferrari and TIER 2 for all other OEM (Tesla, BMW, Stellantis etc…)

Our sectors are very diversified, we produce not only for the automotive industry but also for household appliances, electronics, IT and aerospace.

Products

Design

Processes

Quality

NUOVA SIMACH S.r.l. is in Torre Canavese (Turin), Italy and covers an area of 11.000 square meters. Our Company was founded in 1977 and it is specialized in cold stamping of metal parts, from tool design and construction to mass production.

We are leaders in the production of contacts, fastons, also selectively treated, made from tape.

We produce busbars, brackets, supports, shields, covers, safety belts and, especially for vehicle electrification, we are specialized in copper, aluminum and steel stamping parts from 0.07mm to 6mm in thickness.

We support our customers from prototypes to mass production (co-design phase included). We carry out manual assemblies or arc welding with different technologies (MIG / TIG / Short Arc welding / projection welding for nuts. We can also provide customized packaging for different types of products.

We are supported by external suppliers for different special processing: total or selective treatments such as coating, insulation, galvanizing, tinning, nickel plating, silver and gold selective plating, gilding, varnishing, degreasing, burnishing etc..

We are direct supplier (TIER 1) of Volkswagen group (Lamborghini, Audi etc) and Ferrari and TIER 2 for all other OEM (Tesla, BMW, Stellantis etc…)

Our sectors are very diversified, we produce not only for the automotive industry but also for household appliances, electronics, IT and aerospace.